How to Repave a Concrete Roadway Remove Debris. If a crack measures less than a quarter of an inch, it's the best candidate for simple repaving. Wet the driveway with a pressure washer. A sand mix or concrete grinder, which does not contain gravel, can be used if the area to be repaired is not large or deep.

A standard concrete mix containing gravel works best for patching large or deep areas. Pour enough dry concrete mix into a 5 gallon bucket to repair cracks and repair damaged areas. You will need some clean gravel with stones that vary in size, from grapes to peas. Mix three parts gravel with two parts sand and 1.5 parts cement.

Mix all this dry and add water until the concrete has the consistency of a hard applesauce. You can watch a video about concrete mixing, in which I show the perfect consistency. You can also purchase concrete repair putty, concrete crack repair epoxy, concrete repair mixes and latex patch material. For larger cracks, you will need to use a mortar mix.

Although it seems contradictory, cracks and holes in concrete driveways cannot be repaired with normal concrete. Concrete Network explains that this falls between patching and replacing and can make entries look like new. Keep in mind that any repairs are temporary, although some will last longer than others, possibly many years. A garden full of bamboo plants was the inspiration for this concrete entrance layer, which is patterned with a pattern of bamboo leaves on a light stone texture.

In this project, the concrete doorway was dyed in a warm walnut shade to accentuate existing cracks and give it a rich leather-like look. After that, filling small cracks is an easy DIY project, but for the best results, watch this concrete crack repair video before you start. Before starting any driveway repair project, the first and most important step is to figure out what caused the damage and then determine the best repair procedure to resolve the problem (read this troubleshooting tip). Patching driveways requires more time, effort, and expense, but you can still make this a DIY project with a hammer, chisel, wire brush, trowel, straight-edged board, and concrete bonding liquid.

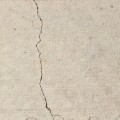

Although concrete is a durable surface, concrete driveways deteriorate and develop cracks over the years. Improper subgrade preparation, poor concrete mix, or shrinkage during cure are factors that can cause cracking and shunting due to improper initial installation of an inlet. You should also understand that cement is a component of concrete, but that it is almost certain that the driveway itself is not composed solely of cement. Spray the cleaner onto the concrete surface with a low-pressure nozzle following the instructions on the container.

As long as the rest of the driveway is in good condition (no shaking, sinking, or crumbling), you can replace those small cracks with a smooth concrete surface by applying a high-quality repaving product, such as the Quikrete Concrete Repaver. Typically limited to a small area, these cracks are good candidates for repair with Quikrete's fast-setting cement mixed with acrylic fortifier. As long as your entry is structurally sound, there are ways to repair minor and even major defects without tearing it out and replacing it completely. Fortunately, filling in the cracks in a concrete driveway is a simple and relatively inexpensive DIY project.

This cement-based product contains polymer modifiers and additives that are designed to form a durable and permanent bond with existing concrete. .